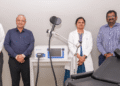

Rajiv Ganju, Senior Vice President Manufacturing and Global Supply Chain, and Ganesh Moorthi, Chief Technology Officer at Luminous Power Technologies, say the new facility strengthens precision manufacturing, digital traceability, and next-generation battery capabilities

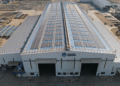

India’s push toward advanced energy storage and clean mobility received a boost with the inauguration of a lithium-ion battery assembly line by Luminous Power Technologies at its manufacturing facility in Baddi, Himachal Pradesh. The new line marks the company’s first lithium-ion battery assembly operation and represents a significant step in strengthening its next-generation energy storage capabilities.

The lithium-ion assembly line has an installed production capacity of 500 megawatt hours and integrates advanced robotic automation with precision-led manufacturing processes. According to the company, the facility has been designed to meet high standards of quality, safety, and performance across lithium-ion battery packs.

The new line is capable of manufacturing standalone lithium-ion battery packs, stationary Battery Energy Storage Systems, and automotive battery packs for e-rickshaw applications. It supports capacities ranging from 1.2 kilowatt hours to 16 kilowatt hours for individual battery packs, with system-level scalability up to 1 megawatt hour. This enables applications across residential, commercial and industrial energy storage, as well as electric mobility use cases.

Rajiv Ganju, Senior Vice President Manufacturing and Global Supply Chain at Luminous Power Technologies, said the commissioning of the lithium-ion assembly line strengthens the company’s integrated manufacturing and supply chain capabilities. He said the facility reflects Luminous’ focus on precision, localisation, and building future-ready manufacturing operations to support India’s evolving energy requirements.

A key feature of the assembly line is end-to-end digital traceability for every battery pack manufactured at the facility. The system is aligned with the latest Battery Aadhaar requirements, enabling full lifecycle tracking and strengthening regulatory compliance, transparency, and consumer confidence.

Ganesh Moorthi, Chief Technology Officer at Luminous Power Technologies, said the new assembly line marks the beginning of a long-term journey in next-generation energy technologies for the company. He said the facility integrates advanced automation with multiple quality evaluation technologies and is designed to remain scalable as energy storage requirements evolve.

Beyond manufacturing, the lithium-ion assembly line is expected to contribute to Luminous’ sustainability objectives. The facility supports renewable energy storage deployment, electric vehicle applications, and grid-level storage, while improving manufacturing efficiency through automation. The company said the line will also support circular economy practices through battery recycling and component reuse.

The operationalisation of the assembly line is expected to generate employment and contribute to local economic development in the Baddi region. The facility further strengthens Luminous’ positioning as a full-stack consumer energy fulfillment company, supporting India’s transition toward cleaner, more efficient, and future-ready energy systems.

At Prittle PrattleNews, featuring you virtuously, we celebrate the commitment and innovation. Led by Editor-in-Chief Smruti Bhalerao, our platform is dedicated to sharing impactful stories that inspire change and create awareness. Follow us on LinkedIn, Instagram, and YouTube for more stories that matter.

1 Comment