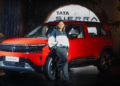

Dr Anupam Agnihotri of JNARDDC said over 70 companies have registered under the Rs 1,500 crore incentive programme

The government’s Rs 1,500 crore Critical Mineral Recycling Incentive Scheme has begun gaining traction across the recycling industry, with more than 70 companies registering since its operational rollout, according to officials speaking at IMRC 2026 in Jaipur.

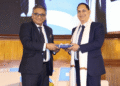

Addressing the International Material Recycling Conference 2026 organised by the Material Recycling Association of India, Dr Anupam Agnihotri, Director of the Jawaharlal Nehru Aluminium Research Development and Design Centre, said the scheme has moved from policy announcement to implementation, with eligibility norms and incentive structures now clearly defined.

The Critical Mineral Recycling Incentive Scheme, announced by the government in October 2025 and operationalised through guidelines issued shortly thereafter, is designed to promote domestic recycling and recovery of critical minerals at a time when global supply chains are tightening. According to Dr Agnihotri, more than 10 recycling companies have already received formal acknowledgements under the scheme, reflecting early industry confidence.

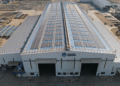

Dr Agnihotri said the scheme targets the creation of 2.7 lakh metric tonnes of recycling capacity and introduces a differentiated incentive framework based on company scale. Group A recyclers, defined as companies with an annual turnover exceeding Rs 200 crore, are eligible for incentives of up to Rs 50 crore or 20 percent of plant and machinery costs, whichever is lower. Group B recyclers, with turnover below Rs 200 crore, can access incentives of up to Rs 25 crore or 20 percent of plant and machinery costs.

With operational guidelines now in place under the National Critical Mineral Mission, speakers at the conference underlined that recycling, rather than primary mining alone, will be central to India’s ability to secure long-term access to critical minerals.

“India has identified 24 critical minerals, many of which remain fully or largely import-dependent, making scrap availability, processing and recovery a strategic priority,” Dr Agnihotri said. He added, “There is a narrow window of five to six years. Countries are already moving towards resource nationalism. Soon, they will restrict exports not just of ores but also of scrap and waste. India must act now to build domestic recycling and recovery capacity if it wants secure supply chains.”

Explaining the design of the incentive framework approved by the Union Cabinet in September 2025, Dr Agnihotri said the scheme prioritises quality and technological capability over rapid volume expansion. “Only R3 and R4 category recyclers are eligible. Group A recyclers must process at least 10,000 tonnes per annum, while Group B recyclers must process a minimum of 5,000 tonnes, with defined purity benchmarks. Incentives are capped at Rs 50 crore or 20 percent of plant and machinery cost, ensuring support is directed toward serious, technology-driven recycling investments,” he said.

The scheme combines capital expenditure-linked incentives with phased operational expenditure support over a five to six year period. Incentives are restricted to entities engaged in actual extraction and recovery of critical minerals, excluding black-mass-only operations. Dr Agnihotri said this structure is intended to provide stability for recyclers investing in advanced scrap-processing infrastructure.

Placing the initiative in a broader global context, Dr Agnihotri said critical minerals have emerged as a determinant of geopolitical and economic power. “The green transition, EV manufacturing, Industry 4.0 and defence technologies all depend on reliable access to critical minerals. Recycling and urban mining will increasingly define national competitiveness,” he said.

He added that JNARDDC, an autonomous body under the Ministry of Mines, has been designated as the nodal agency for recycling across aluminium, copper, lead and zinc, with recycling and critical minerals formally added to its mandate. “From funding startups beyond TRL-3 to supporting pilot plants through nine Centres of Excellence with financial backing of up to Rs 20 crore, the institutional ecosystem for scrap-based recovery is now firmly in place,” he said.

Offering an international perspective, Dr Rachana Arora, Director Climate Change and Circular Economy at GIZ India, said India’s recycling-led approach reflects shifting global supply chain realities. “Critical raw materials are no longer a single-country issue. India and the European Union are moving toward coordinated approaches on batteries, renewables and electronics, with recycling and urban mining emerging as common priorities,” she said, citing India Germany cooperation across exploration, processing, recycling and technology development.

On the technology front, Dr Alok Ranjan Paital, Principal Scientist at CSIR CSMCRI, said the policy push aligns with recycling technologies that are ready for scale-up. “Hydrometallurgy remains central to battery recycling, but advanced processes such as direct cathode-to-cathode regeneration can further reduce energy use and material loss, provided purity challenges are addressed,” he said.

From an industry standpoint, Vijay Pareek, Executive Director and SBU Head at Gravita India Limited, said the incentive scheme provides long-awaited clarity. “Clear eligibility norms, incentive structures and timelines provide confidence to investors and recyclers, accelerating formalisation and capacity creation in scrap-based recovery,” he said.

IMRC 2026 is being held from January 20 to 22, 2026, at the Novotel Jaipur and Convention Centre in Jaipur, bringing together policymakers, recyclers, manufacturers and global stakeholders. Speakers agreed that developments since September 2025, including notification of guidelines, opening of applications through April 2026, establishment of Centres of Excellence and expanding international cooperation, mark a structural shift in India’s mineral strategy, with recycling positioned at the core of critical mineral security.

On the sidelines of the conference, the MRAI Battery Recycling Excellence Awards 2026 were presented. Ardee Industries Limited was named Recycler of the Year in the MSME category, while Gravita India Limited received the Recycler of the Year award in the large scale category.

At Prittle PrattleNews, featuring you virtuously, we celebrate the commitment and innovation. Led by Editor-in-Chief Smruti Bhalerao, our platform is dedicated to sharing impactful stories that inspire change and create awareness. Follow us on LinkedIn, Instagram, and YouTube for more stories that matter.